![]() Titan Battery Minerals Technology welcomes you to the second edition of Titan BMT News.

Titan Battery Minerals Technology welcomes you to the second edition of Titan BMT News.

We are sharing Battery Minerals Technology news headlines, highlighting the role Manganese is playing in world commodity and resource markets.

We have three News Features in today’s edition:

-

5.4% of a typical EV Battery is Manganese – Visual Capitalist

-

All eggs in one basket? Threats to the Battery Mineral Supply Chain – IEA Report

-

Interest in the forgotten Battery Material – Manganese – increases dramatically – Fastmarkets

The aim of Titan BMT News is to help inform our markets of the uses of Manganese globally, as Titan BMT’s flagship project is the Los Pumas Battery Metals Manganese Project in Northern Chile, with a current resource of 30.26 million tonnes of ore.

Onto the Headlines…

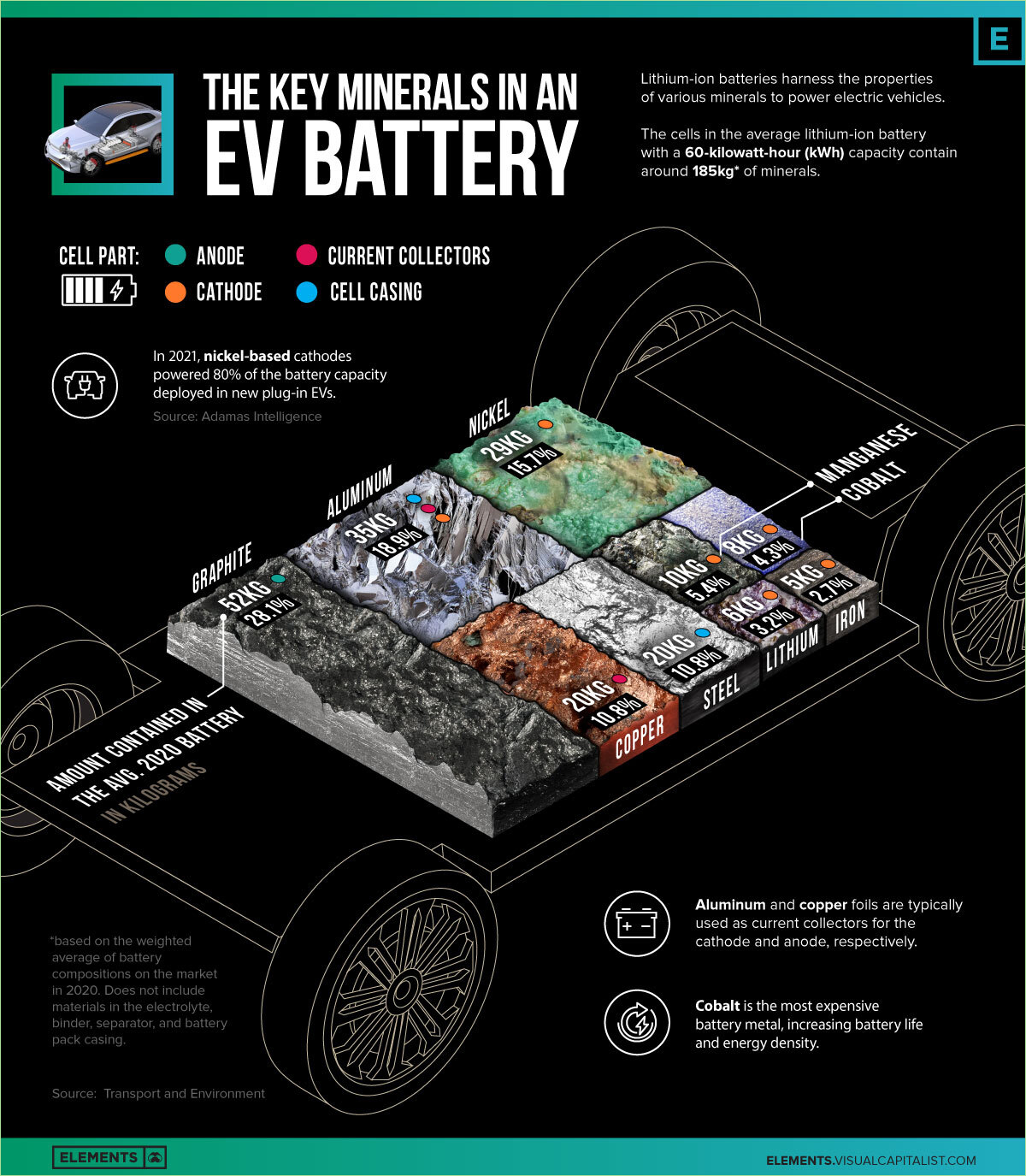

1. The Key Minerals in an EV Battery? – Visual Capitalist

Source: Elements Visual Capitalist May 2022

This graphic displays the makeup of a typical Lithium-Ion Battery, with Manganese elements contributing 5.4% in a 60-kilowatt-hour (kwh) capacity battery (10kg of 185kg).

This infographic uses data from the European Federation for Transport and Environment to break down the key minerals in an EV battery. The mineral content is based on the ‘average 2020 battery’, which refers to the weighted average of battery chemistries on the market in 2020.

From EVC:

Cobalt and Manganese often act as stabilizers in NMC batteries, improving their safety.

Inside practically every electric vehicle (EV) is a lithium-ion battery that depends on several key minerals that help power it.

Some minerals make up intricate parts within the cell to ensure the flow of electrical current. Others protect it from accidental damage on the outside.

![]() Titan BMT Director Natalie Dawson comments:

Titan BMT Director Natalie Dawson comments:

“With a current Manganese resource of 30.2mt (at 6.24% Mn), our Los Pumas Battery Metals Project in Chile is shaping up to be a key component in the mass production of EV batteries.

Going forward, we expect low-cost manganese cathode technology to significantly contribute to lowering the unit cost per kWh of energy storage both for existing lithium-ion batteries but also for newer battery technologies such as sodium manganese batteries.”

===

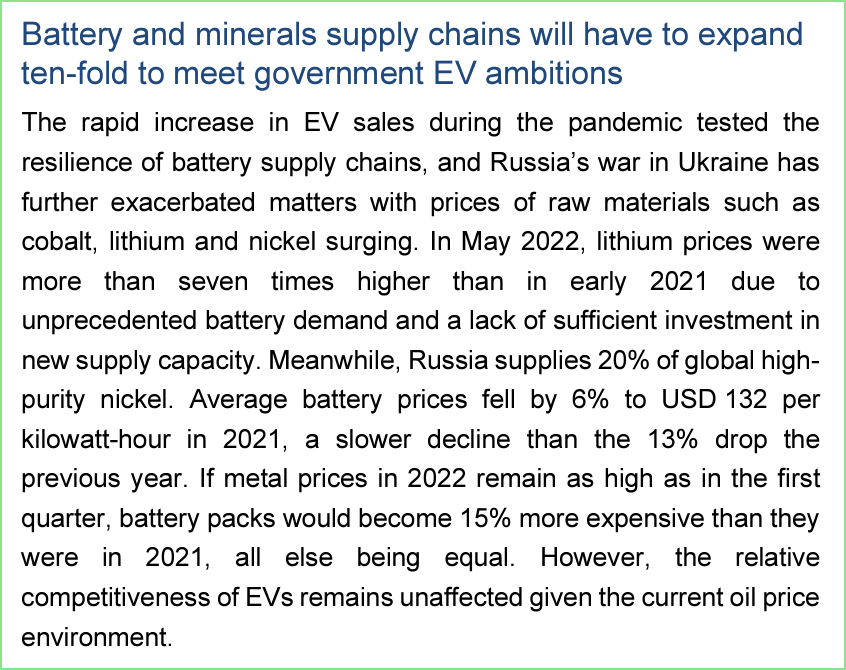

2. Supply chain for Battery Metals still focused on limited markets – International Energy Agency Report.

The International Energy Agency (IEA) released the following report detailing the Global Supply Chain of EV Batteries – July 2022.

This special report by the International Energy Agency that examines EV battery supply chains from raw materials all the way to the finished product, spanning different segments of manufacturing steps: materials, components, cells and electric vehicles. It focuses on the challenges and opportunities that arise when developing secure, resilient and sustainable supply chains for electric vehicle batteries and reviews government targets and strategies in this area.

![]() Titan BMT Director Natalie Dawson comments on key takeaways from the IEA report:

Titan BMT Director Natalie Dawson comments on key takeaways from the IEA report:

“Threats to Battery Mineral supply chain that will impact the global emissions targets, are real.

The time is now for investors, consumers, miners, manufacturers to look beyond the existing markets and look to innovate to create more robust and sustainable supply chain channels.

As reported by the IEA, the supply chain of Battery Minerals are still focused on limited markets, China, Russia and DRC.

Risks to such a vital supply chain suggests we may have forgotten the lessons of the pandemic, by once again putting all our eggs in one basket when it comes to supply chain channels.”

===

3. Volatility expected in Manganese sulfate amid supply and processing capacity bottlenecks – Fastmarkets

From Fastmarkets – July 25, 2023

Sometimes regarded as the ‘forgotten’ battery material, attention towards manganese has increased drastically as participants seek to localize supply chains and ramp up battery production to meet growing demand.

Manganese sulfate is a key material component of some lithium-ion battery chemistries, particularly nickel, manganese, cobalt (NMC) cathodes, providing stability to the cathode during cycles, enabling greater range.

In this series, which will comprise of three parts, Fastmarkets will explore the current market dynamics in manganese sulfate markets, as well as future applications and battery chemistries.

Like many battery raw materials, manganese metal (which Fastmarkets prices as electrolytic manganese flake) consumption has historically been dominated by the alloy steel sector rather than lithium-ion batteries. Part of the reason that battery grade manganese does not often dominate discussions in the battery raw materials market is due to its apparent abundance of supply, though it is highly concentrated in China.

Part of the reason that manganese does not often dominate discussions in battery raw materials is due to its apparent abundance of supply, though it is highly concentrated in China.

Other regions are expected to see production growth, but China’s dominant position is likely to remain unchanged by the end of the decade.

![]() Titan BMT Director Natalie Dawson comments:

Titan BMT Director Natalie Dawson comments:

“QUOTE”

====

Have you seen a news item relating to Battery Minerals Technology you think we should share?

News Release

24 August 2023

Please follow us on Twitter and LinkedIn.

=========

![]() About Titan Battery Minerals Technology – we are a dedicated, globally focused battery minerals and technology company.

About Titan Battery Minerals Technology – we are a dedicated, globally focused battery minerals and technology company.

Our flagship Los Pumas Battery Metals Manganese Project will convert high-quality manganese mineral resources into High-Purity Manganese Sulphate Monohydrate to supply the Electric Vehicle and battery energy storage markets. In May 2023 – a substantial JORC mineral resource upgrade for Los Pumas was reported with 30.26 million tonnes of ore, including 23.3 million tonnes in the indicated category.

Contact the Company Secretary for more information on Titan BMT and Los Pumas.